Do the results of your nanoindentation or scratch test not match the results from the real-life application?

Do your coatings successfully pass all standard or industry tests (e.g. DIN EN ISO 6508-1, DIN EN 1071-3, ASTM C1624, DIN EN ISO 14577, ISO 26443, DIN EN ISO 6507, DIN EN ISO 4516, ASTM E2546, ISO 20502) during quality assurance, but catastrophically fail in field tests or even in use?

Do your indenter tips break away often or wear off quickly (e.g. on hard DLC coatings)?

Luckily, it is well known nowadays that a standard Rockwell test or a high-load Vickers test do not give any information about thin films. And many are aware that the 10% rule does not apply to modulus of elasticity (max. 10% indentation depth of layer thickness). But how should your measurements be dimensioned (e.g. normal force, indenter tip, radius, tip rounding, etc.) in order to learn as much as possible about your coatings and reproduce the failure happening in real-life (e.g. coating failure, adhesion failure, and so forth)? What should be specifically noted when performing measurements (e.g. minimum distance between measurement positions, minimum number of measurements) so that you obtain as undistorted and significant results as possible?

The TestOptimizer module will answer all these questions for instrumented indentation measurements (e.g. nanoindentation, micro indentation, hardness test, …) and scratch tests.

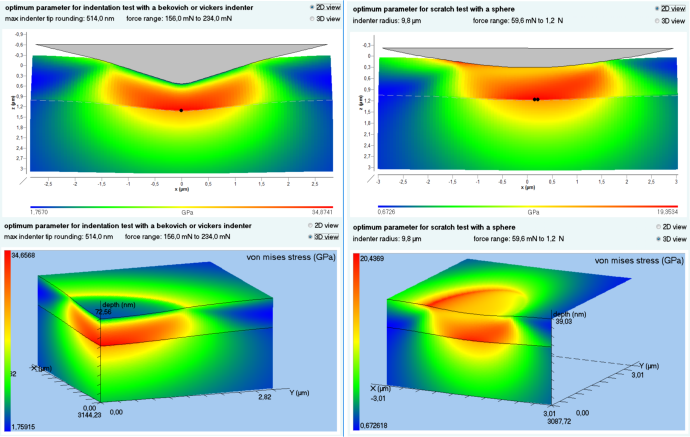

Two of several result pages of Test Optimizer, showing optimal parameters for adhesion failure investigation by nanoindentation with Berkovich or Vickers indenter tip (left column) and scratch test with spherical stylus (right column).

Unfortunately, many standard or industry tests are not or only ill suited to coatings – particularly thin films – or they lack physical substance. The following is a short excerpt of examples of such insufficient standards:

- Rockwell hardness test HRC as per DIN EN ISO 6508-1

- determination of adhesion by scratch test as per DIN EN 1071-3 or ASTM C1624

- determination of hardness by instrumented indentation as per DIN EN ISO 14577

- evaluation of adhesion by Rockwell indentation as per ISO 26443

- Metallic materials – Vickers hardness test DIN EN ISO 6507

- Metallic and other inorganic coatings – Vickers and Knoop microhardness tests DIN EN ISO 4516

- Standard Practice for Instrumented Indentation Testing ASTM E2546

- Fine ceramics (advanced ceramics, advanced technical ceramics) – Determination of adhesion of ceramic coatings by scratch testing ISO 20502

As a consequence of such norms, measurements performed accordingly do, for instance, not contain sufficient coating information (below noise floor), do not result in determination of physical material properties, or do not physically characterize interfaces. Test Optimizer allows you to get around these shortcomings by providing specific key data for each surface measurement. You can determine physical material properties (e.g. real elastic modulus or yield strength of the coating) or generic failure parameters (e.g. physical adhesion, tensile strength, etc.) on the basis of such measurement data by means of FilmDoctor.

Tutorial Videos

The following video gives an introduction to the TestOptimizer module.

Ask us for specific consulting

Mail: info@siomec.de